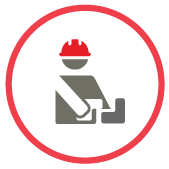

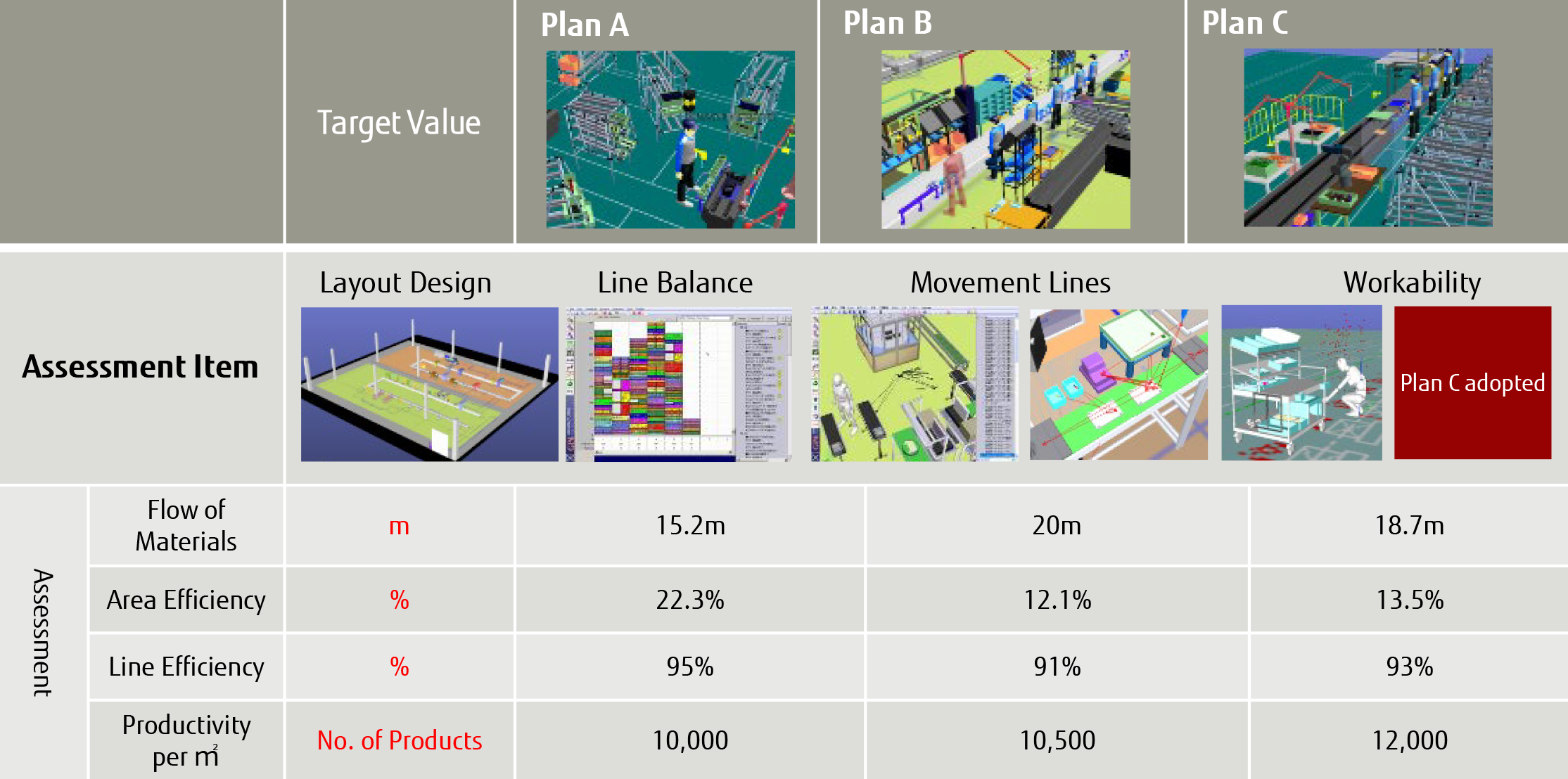

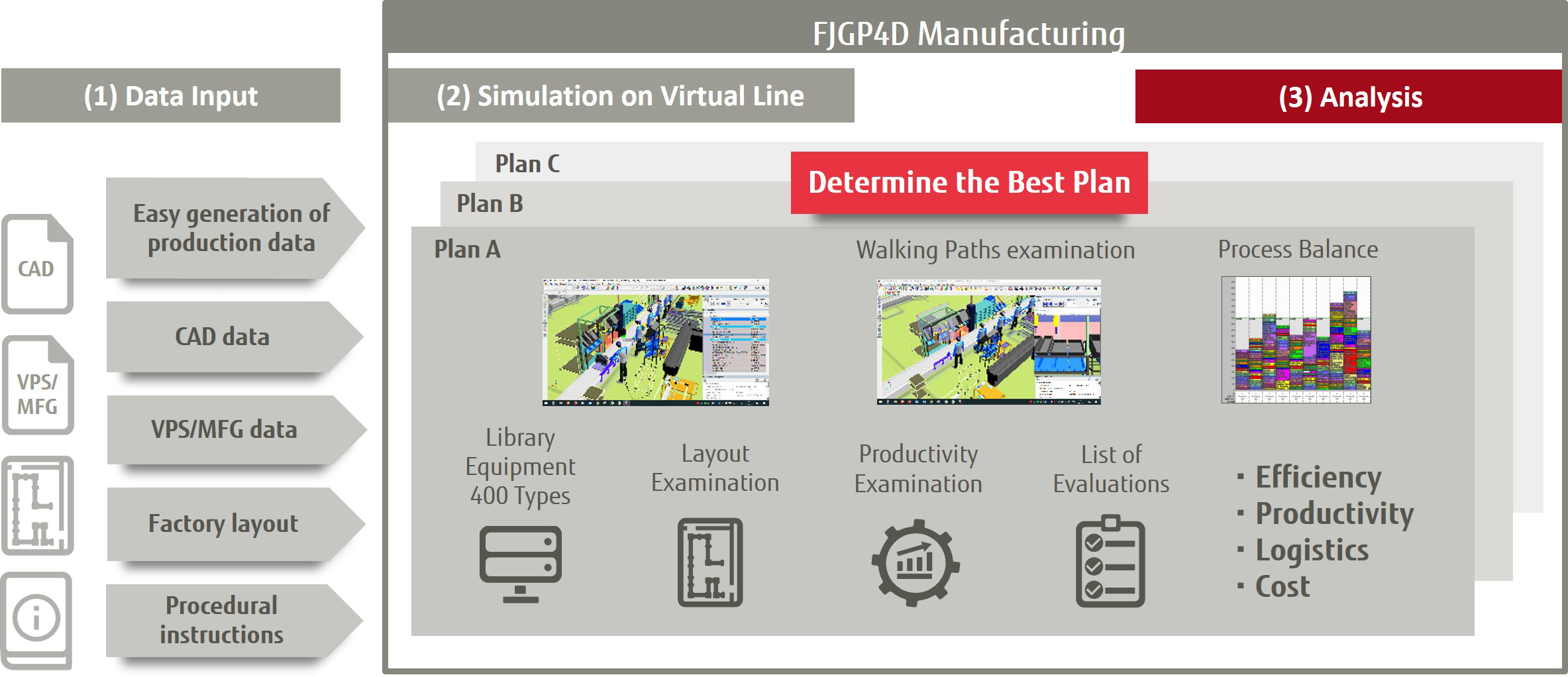

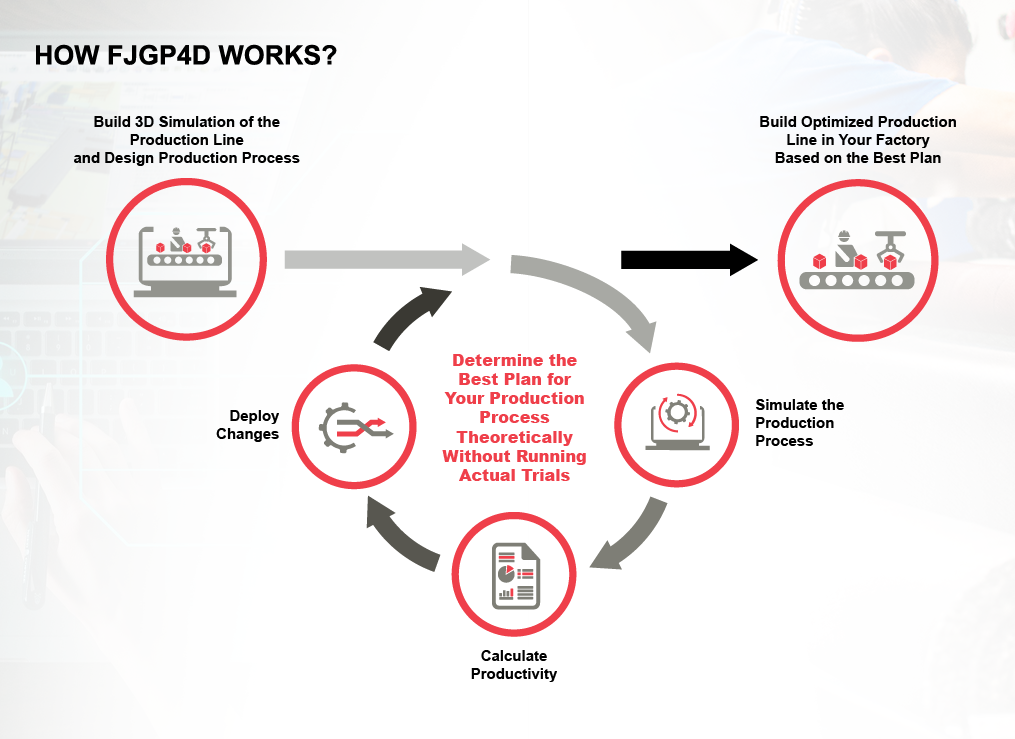

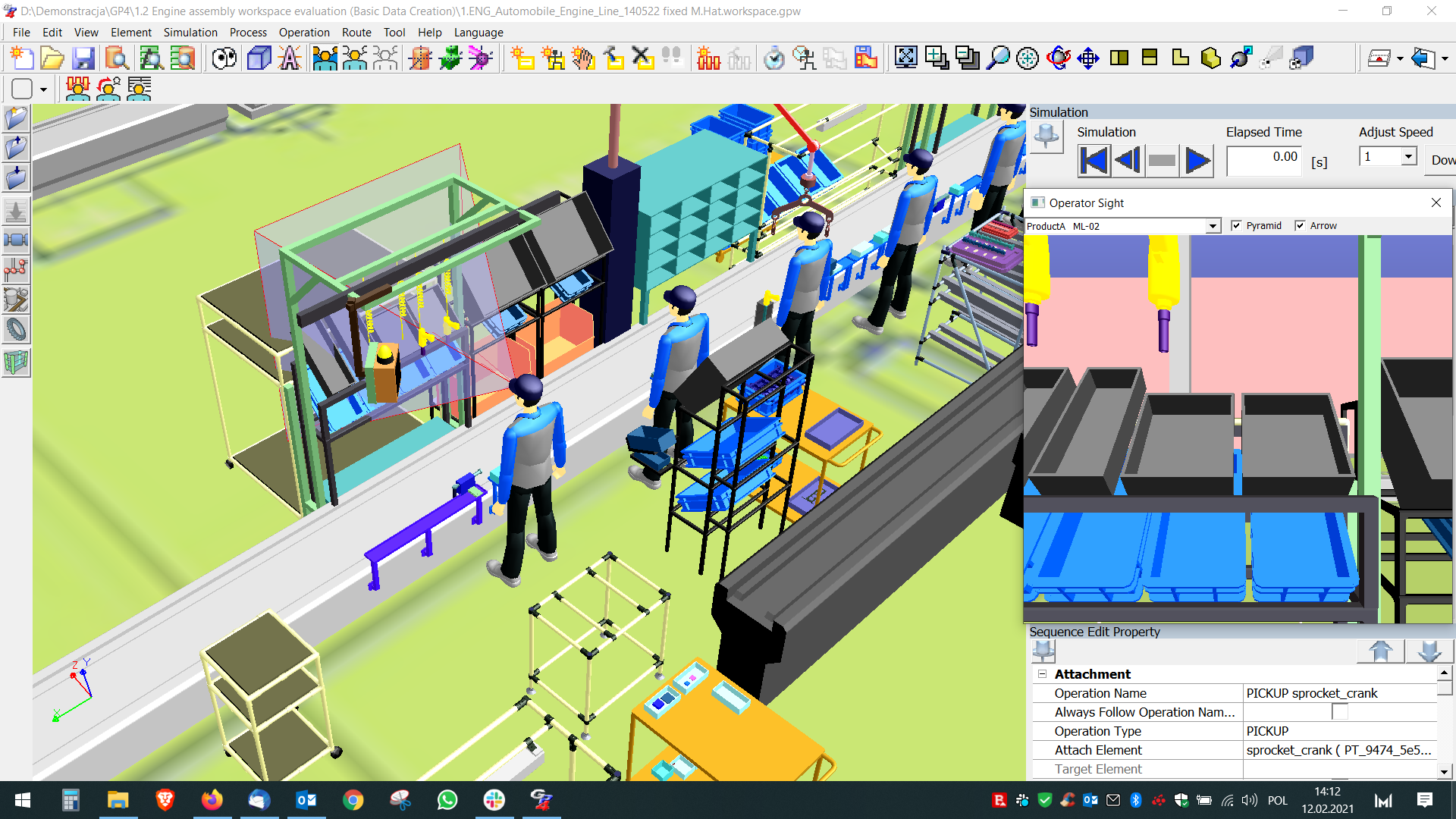

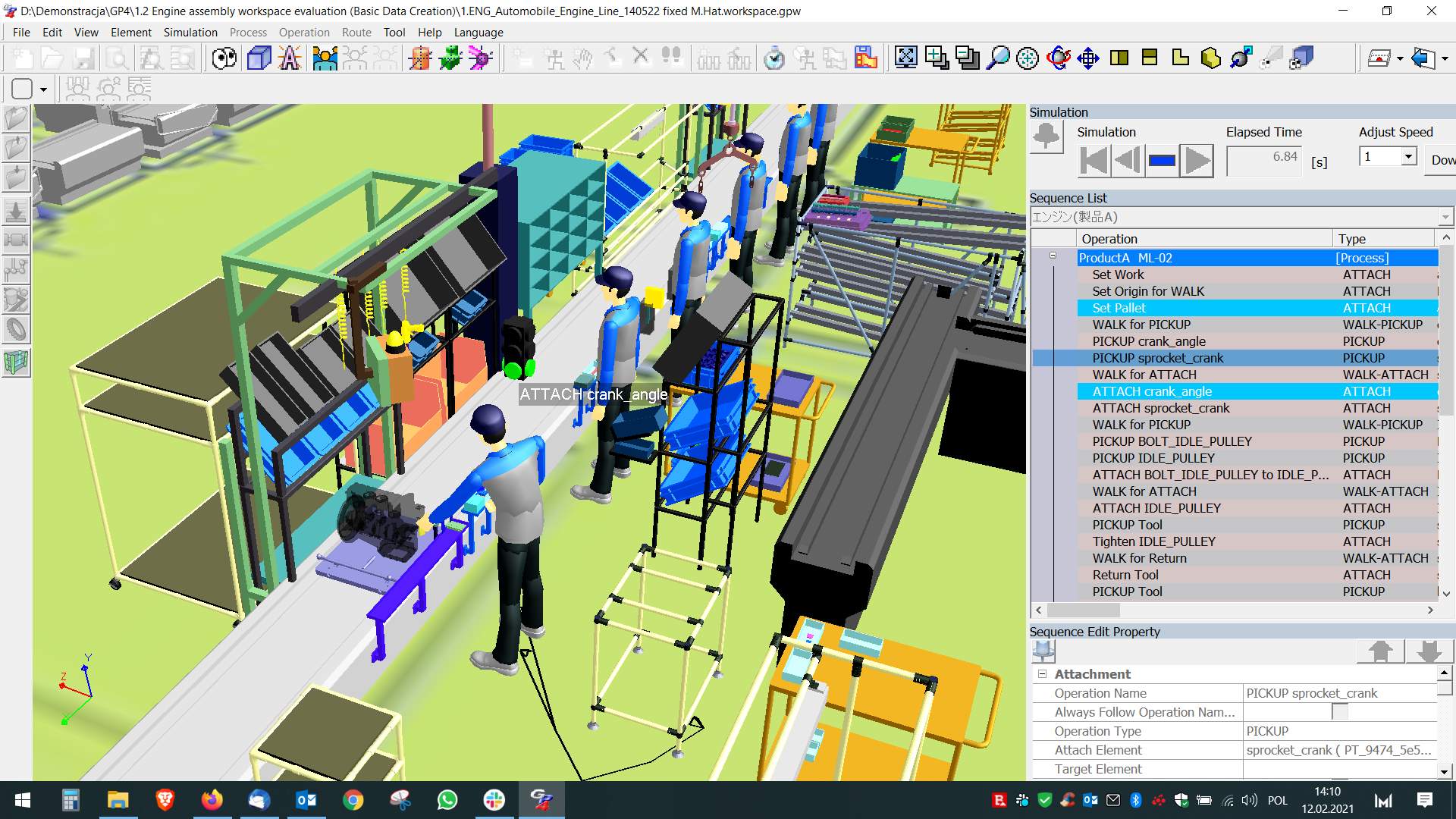

| COLMINA Digital Manufacturing FJGP4D enables us to see both the flow of the products and the traffic of the workers virtually, at the same time. Colmina FJGP4D is a Smart Factory Fujitsu software designed for customers in the manufacturing industry. With FJGP4D users at the production preparation stage can create a virtual production line and run simulations on factors including the most efficient movements or positions of production workers, the optimal alignment of workers in relation to the flow of a production line, and the time required to complete specific production tasks. As a result, in addition to enabling greater efficiency in assembly work on a production line from the standpoint of people, the product enables workers to benchmark their work against the simulation results and share their understanding of problem areas with co-workers, leading to improvements on the front lines of assembly plants. |

| FJGP4D realizes optimization and consensus building through process design and various verifications in virtual space using product CAD data, sequence data, and equipment data converted with FJGP4DSGS (the FJGP4D Manufacturing CAD data conversion application). It also assists efficient preparation for production through the utilization of the resulting output in preparation for production and mass production line development. |

|

|