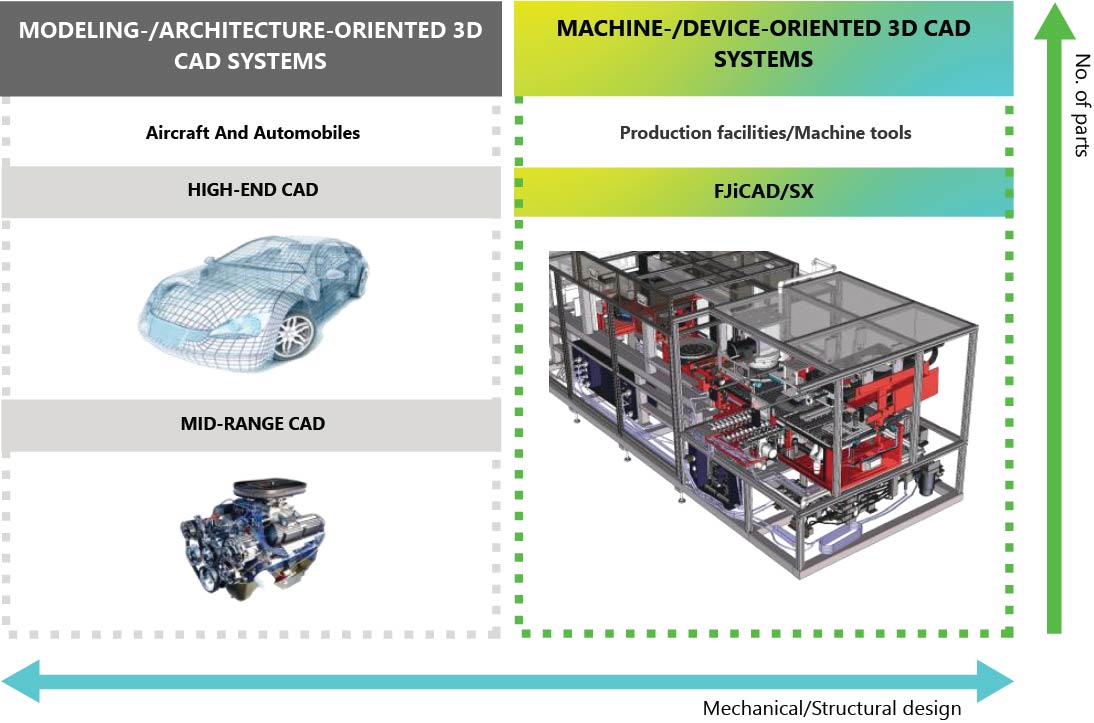

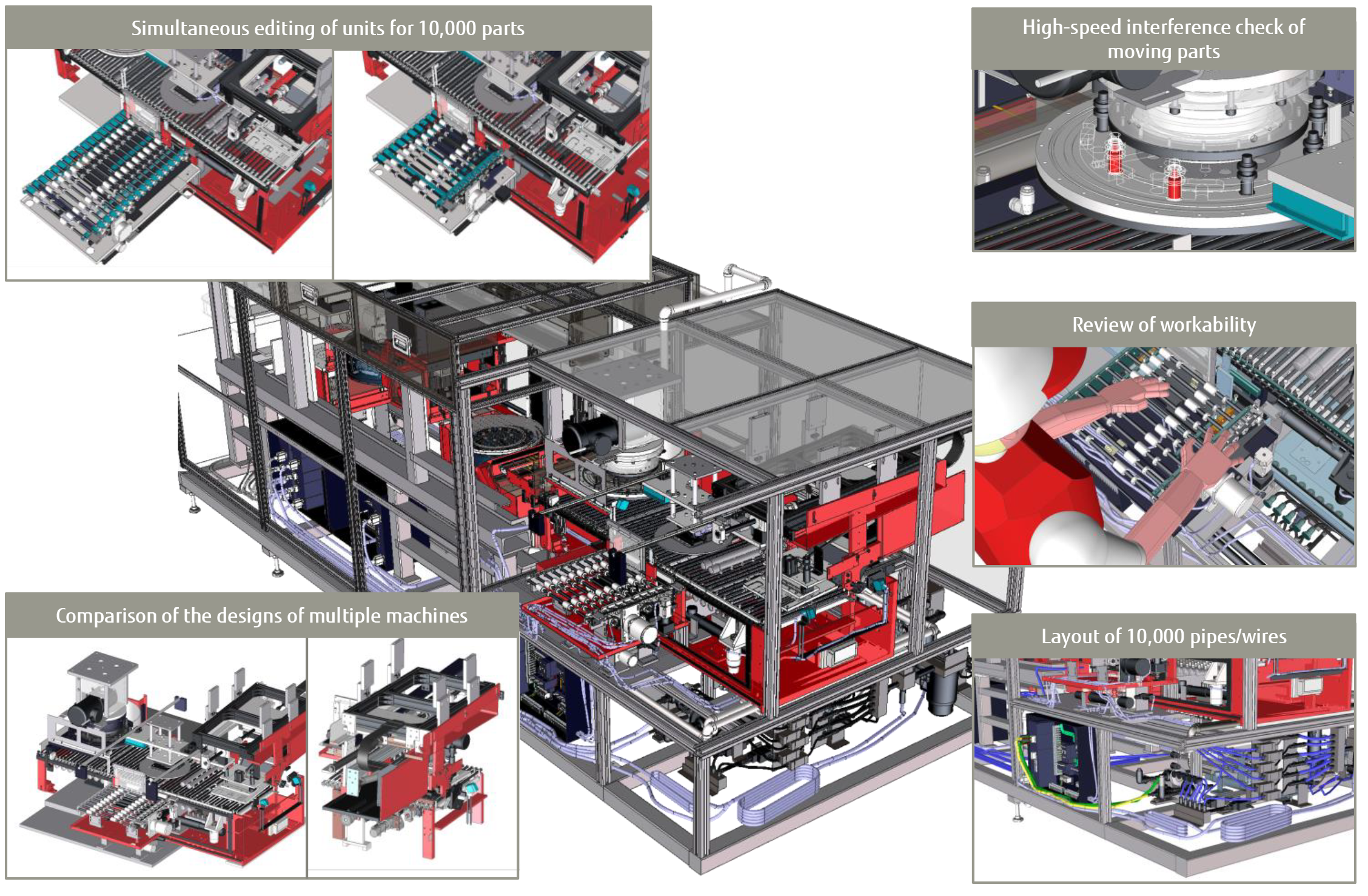

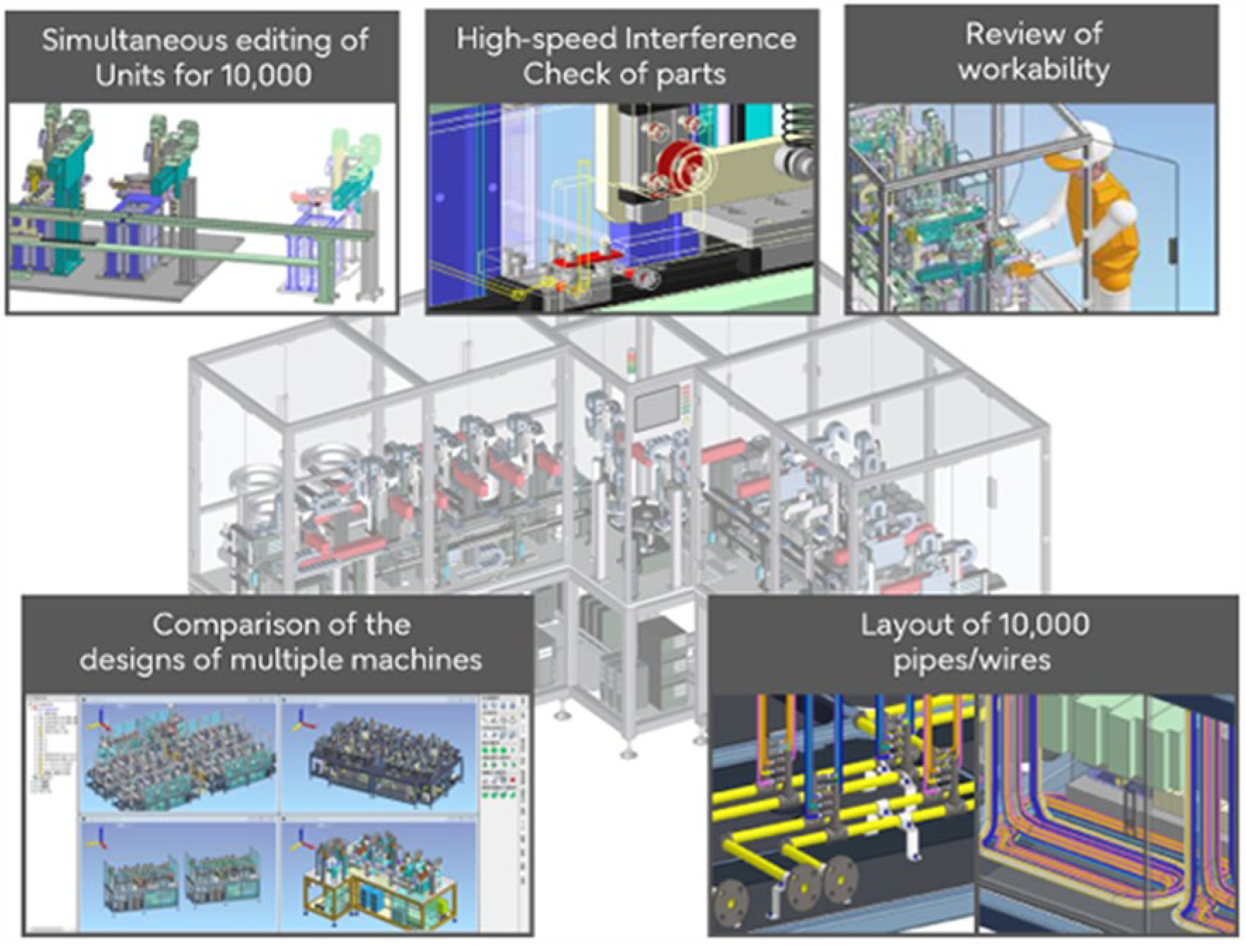

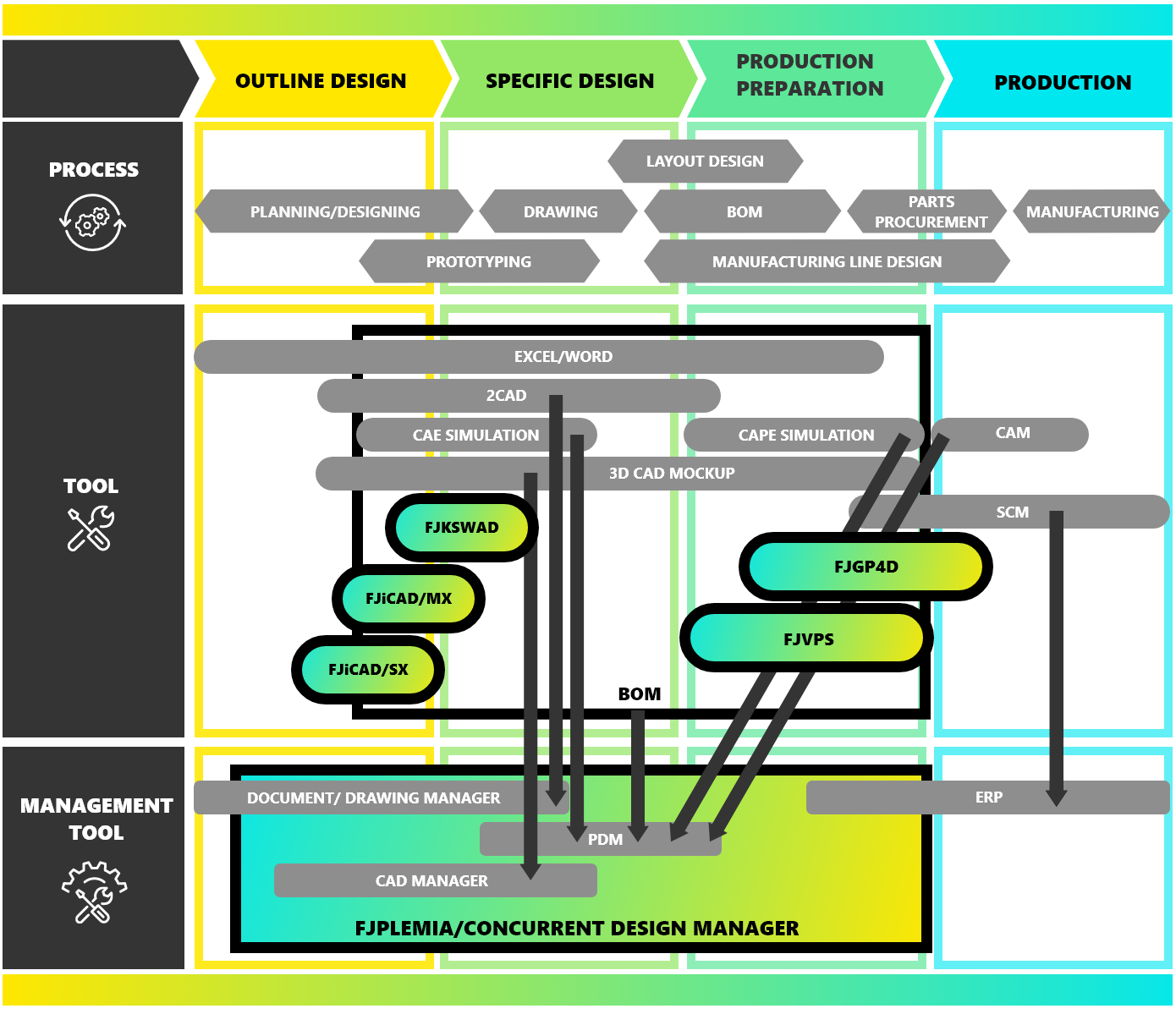

Fujitsu Manufacturing Industry Solution Design & Manufacturing Support FJiCAD/SX is a tool dedicated for manufacturing and industry field, that supports the design process of machinery.

From initial stage of design, motion information including the amount of movement, sequence of movements, and timing of a 3D device model can be directly added to 3D data, enabling examination of movements, processes, and cycle times while confirming the positional relationship with peripheral parts

Recently Fujitsu has additionally developed and implemented new design functions that allow mechanical, electrical, and control designers to keep and utilize operation and manufacturing information, as well as functions that enable the use of 3D data in manufacturing and maintenance services. This enables the smooth sharing of information between departments in a digital environment by connecting common 3D data from design upstream to manufacturing and maintenance services, contributing to the reduction of lead time in the manufacturing industry in the "new normal" era.